Seit der Übernahme von den Rockster R700S Brechanlage, ist die Firma Delta Contracting LTD nicht mehr auf externe Hersteller angewiesen, um das gewünschte Endprodukt zu erhalten. Neben einem mobilen Sieb und einem Entwässerer, schließt der mobiler Prallbrecher R700S einen Kreis der Agregatproduktion und öffnet sämtliche Tore zu nuene Gelegenheiten und Geschäftserweiterung.

R700S completes a cycle for in-house aggregate production

Rockster’s R700S main job at Delta Contracting Ltd is to process river gravel, which is done at a rate of ca. 2500 tonnes per month. The final product is later screened into three different fractions being 20-40mm, 6-20mm and 0-6mm for a concrete or roading aggregate.

“We purchased the crusher for our own operation and to make products for our trucks to deliver and sell. Previously we had to rely on opposition operators to produce product for us. In most cases we have completed the cycle from winning feedstock to crushing to transport to laying on roads or selling to concrete plant operators. Equip2 (Rockster New Zealand Dealer) recommended the R700S, which met our requirements perfectly,” explains Paul.

After processing gravel comes chip sealing

Ein weiterer Einsatzbereich der R700S ist die Herstellung von Zuschlagstoffen zur Späneversiegelung. Für diejenigen, die mit dem Verfahren nicht vertraut sind, ist es eine Möglichkeit, die Asphaltstraße instand zu halten, ihre Lebensdauer zu verlängern und die Risse zu versiegeln, ohne die hohen Kosten für die Renovierung zu übernehmen. Zuerst wird eine dünne Schicht flüssigen Asphalts auf die Straße gesprüht, gefolgt von einem feinen Zuschlag oder „Spänen“, in diesem Fall Kies. Überschüssiger Splitt wird entfernt und dann gepresst, um sich mit dem flüssigen Asphalt zu verbinden. Dies ist eine weitere Möglichkeit, den Brecher für eine Vielzahl von Bauprozessen und Projekten einzusetzen, bei denen ein sauberes Aggregat benötigt wird.

Optimal transport dimensions

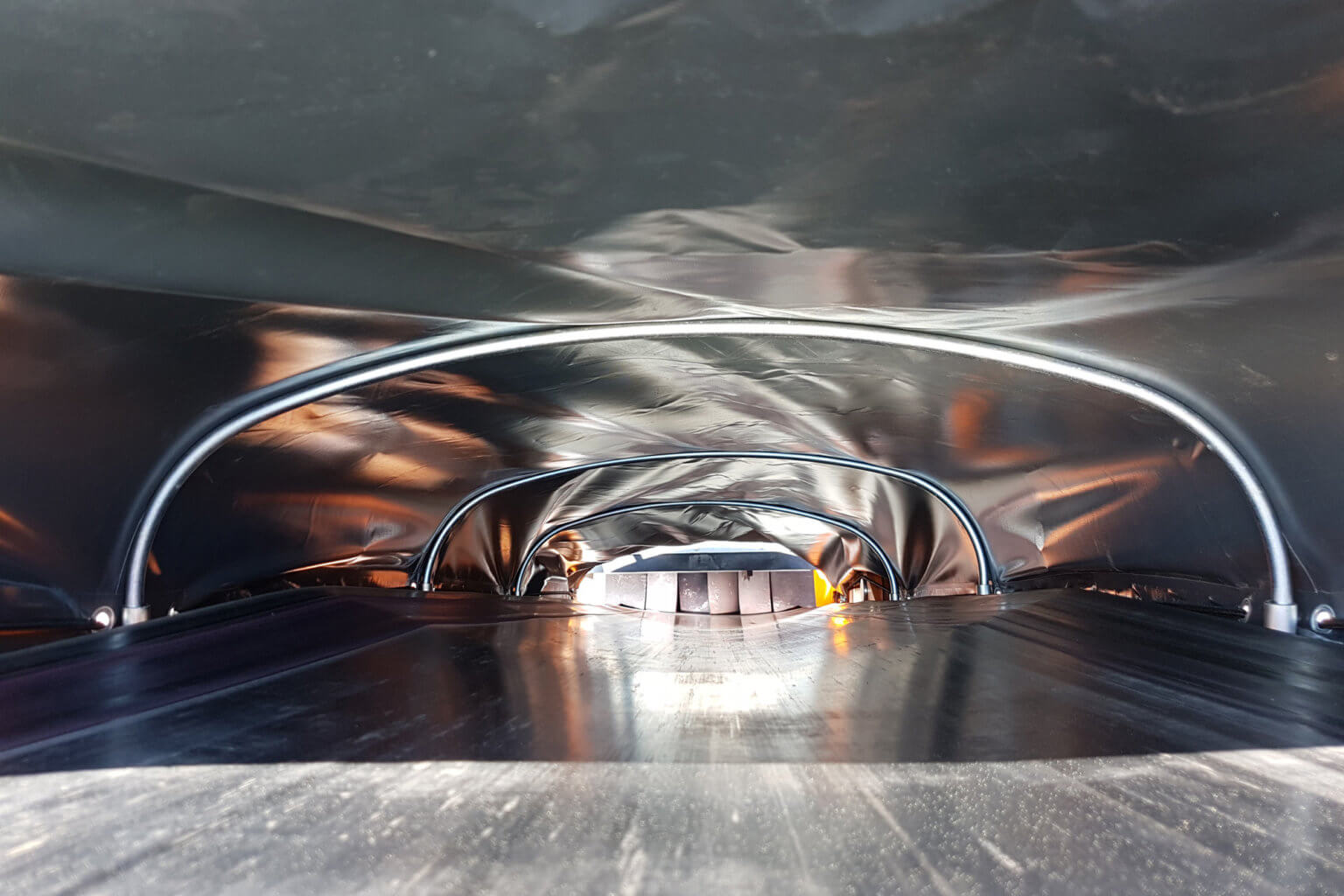

When asked about why Rockster R700S and not any other crusher, Paul responded: “We were looking for an impact crusher with a transport weight under 25 tones and nimble enough to shift from site to site. We are able to transport the R700S on our transport trailers without permits or pilot vehicles so it can be up and running on a new site within a few hours.” As the most compact Rockster impactor, the crusher weighs at 22,8t with the complete Rockster screening system. Its length is only 14,10m, width 2,52m and the height of 3,10m. The transport benefits have been extremely important not only for larger but especially for smaller companies that rely on being independent as well as to satisfy the needs of their customers. Regardless of the terrain, the crusher is extremely easy to load & unload, which makes this impactor very efficient, mobile, and flexible.