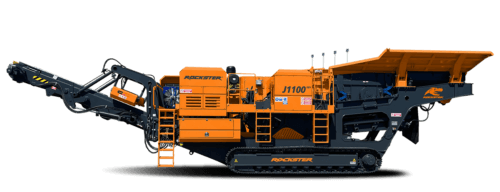

R 800

Tracked

Jaw Crusher

32" x 20"

800 x 500 mm

Inlet opening

bis 120 t/h

depending on material

64.200 lbs

Weight incl. screening system

R 800d

Flexible, Low-wear & Reliable. With the DUPLEX option

- Tier 4 Final / STAGE V Engine - 210kW / 285HP

- DUPLEX-OPTION: Change the impact with the jaw crusher on one machine in less than few hours.

- Hydrostatic crusher drive for consistent throughput

- Adjustment of rotation direction

- Optional Air Blower for seperation of light non-mineral materials

The mobile track-mounted jaw crusher R800 is the ideal solution for any application that demands strong wear parts and least amount of wear. In addition to efficient recycling of construction & demolition waste, the R800 is ideal for applications in hard natural rock.

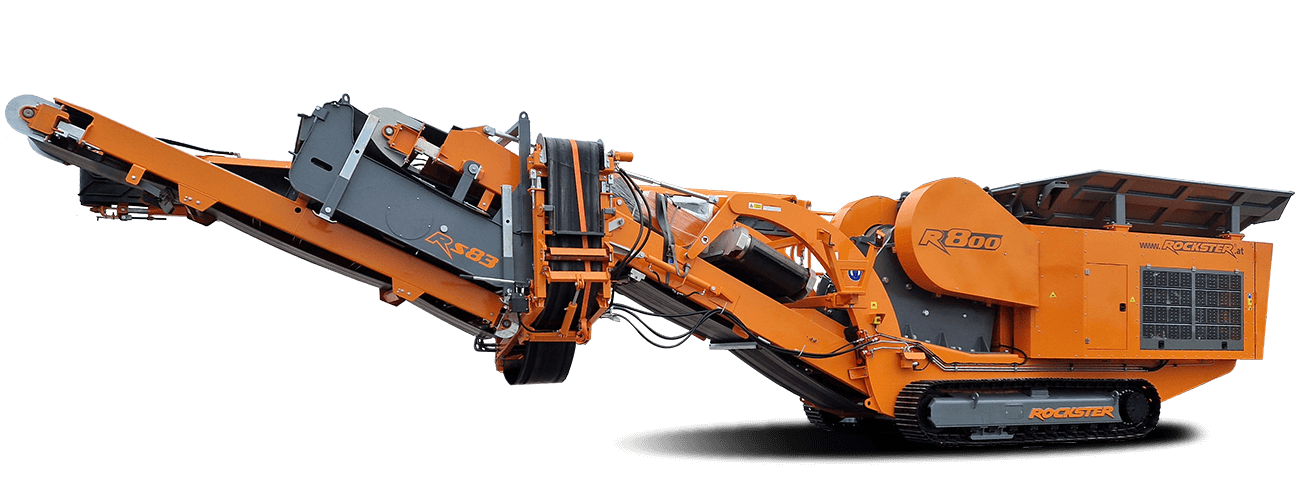

R 800

Technical refinements for an optimal crushing process

Central machine control with a fully authomatic monitoring

Sophisticated and easy-to-use multifunctional color display with various quick start functions (Different settings for a variety of applications)

R 800

Options

RS83 Screen box and RB75 double-functional return-/ stockpile belt

Optimal option for production of 100% defined end-product

Air Blower RVB1700

Efficiently separate light non-aggregates such as plastic, paper, textile, cardboard, wood, ythong, styrofoam, which results in a cleaner and higher quality final product.